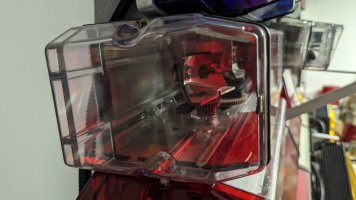

So my pierce alert has the typical heat damaged wiring and also has 1 burned out bulb. I am looking to rebuild it and rewire it.

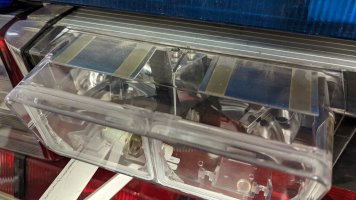

Going to take it apart and polish the lens’ rewire and grease the gears. I have to keep this unique piece in good working order for the display.

The 27 watt bi-pin bulbs with the black tip are hard to find.

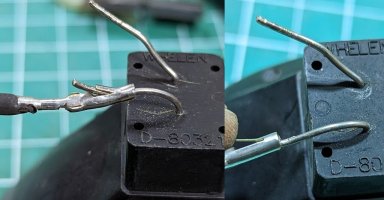

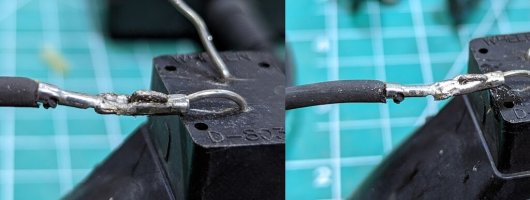

But looking at the wiring it appears the wires have a terminal crimped on the end of the wire to slide over the pin of the bulb. But what throws me off is the terminal looks to have some sort of locking device along with it.

Where can I find these pins?

And any sources of the super flexible wire that is used? Is it 16g silicone covered wire?

There are many knowledgeable people on here but maybe @JohnMarcson has some input.

Thanks

Going to take it apart and polish the lens’ rewire and grease the gears. I have to keep this unique piece in good working order for the display.

The 27 watt bi-pin bulbs with the black tip are hard to find.

But looking at the wiring it appears the wires have a terminal crimped on the end of the wire to slide over the pin of the bulb. But what throws me off is the terminal looks to have some sort of locking device along with it.

Where can I find these pins?

And any sources of the super flexible wire that is used? Is it 16g silicone covered wire?

There are many knowledgeable people on here but maybe @JohnMarcson has some input.

Thanks